NINGBO CHIPEX SEMICONDUCTOR CO.,LTD

Add:No.18 Zhongheng Road,Huaxing District,Andong Industrial Park,Hang Zhou Bay New Zone,Ningbo

P.O:315327

Mail:sales@chipex.cn

Tel:(86)-574-63078606;

(86)-574-63078608-8858

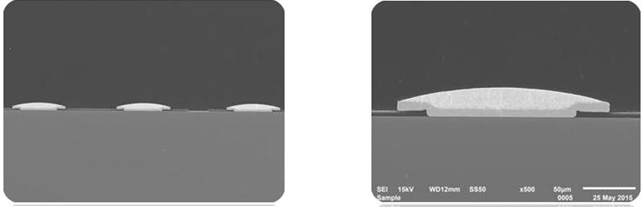

Electroplating solder Technology is making tin bumps on the chip pads by series processes such as coating, litho, electroplating and etching, and then using high temperature melting the bumps and been packaged, the IC size can significantly be reduced by this technology, and has a high density, low induction, low cost, good heat dissipation and so on. Wafer-level chip scale packaging is generally applicable to large-size solder balls placed on large pads and the solder technology applied in the manufacture of fine pitch and ultra-thin package of the small tin ball way. This technology successfully applied to flip and reflected its superiority.

| Solder Bump Structure | Pl Thickness | UBM Thickness | Other |

1M (UBM+Solder Bump) | NA | 8um Cu+Sn | Min.Bumo Pitch:0.15mm Min.Ball Size:0.08mm Min.Ball Height:0.020mm Min.PI Opening:30um Min.Trace Line X Space:10X10UM |

1P1M (PI+UBM+Solder BUMP) | 5um | 8um Cu+Sn | |

2P2M (1st PI+RDL+2ndPI+ UBM+Solder Bump) | 1st PI 5um 2nd PI 10um | RDL:5um Cu UBM:8um Cu+Sn |

APPlication:

Smart Card,VCM Driver,Switch,Audio& Video,EEPROM/Flash/SRAM,MEMS&Sensor,ucontrollers

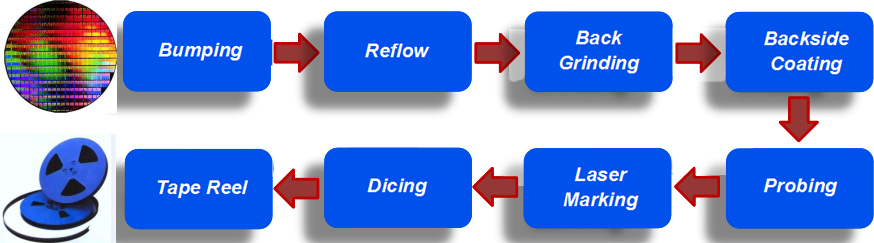

a. Standard Turnkey process: Min. BG thickness 200um, T/R shipment;

b. Special process: Min. BG thickness 60um, Wafer ring shipment.